When Benjamin Gettier ’26 leaves his hometown of Virginia Beach to return to Longwood each semester, he also leaves behind the seas upon which he has piloted boats since he was 8 years old.

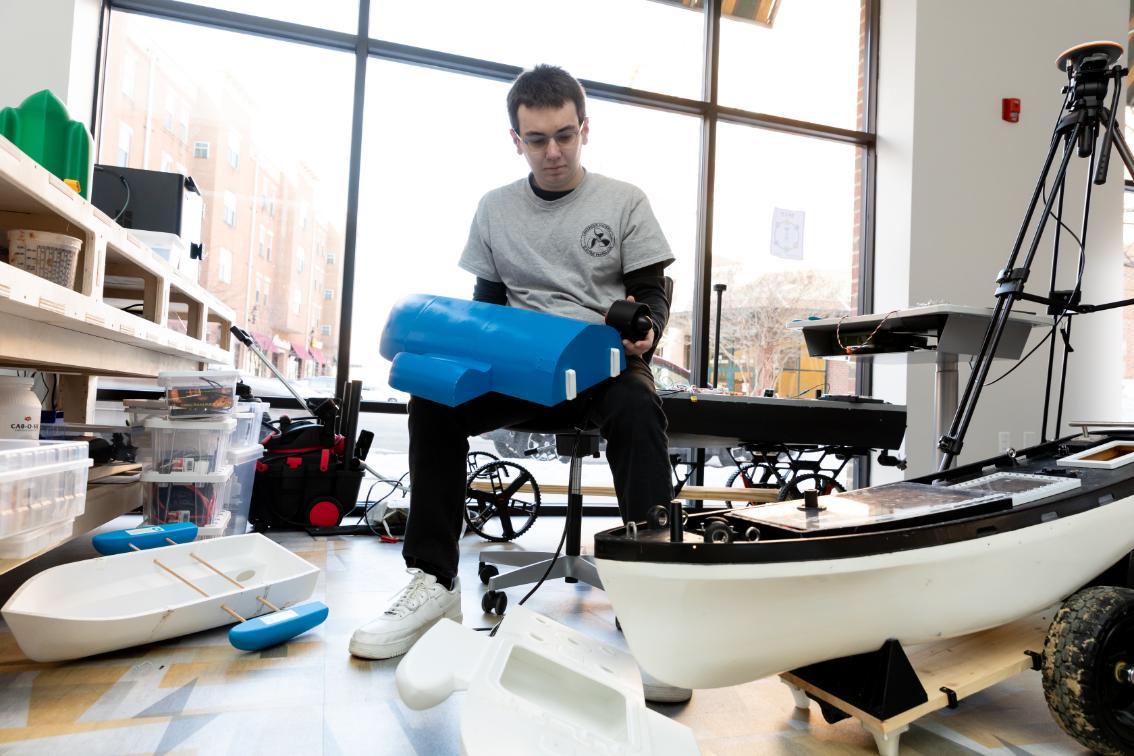

But while he is further removed from his beloved open ocean while on campus, the senior environmental science major has found another way to pursue his aquatic pursuits: fine-tuning prototypes of his own automated boats using the diverse array of tools and resources at the SEED Innovation Hub.

Born from a collaboration between the Longwood Small Business Development Center (SBDC), Longwood University and neighboring Hampden-Sydney College, SEED is a community makerspace and business hub located within walking distance of Longwood’s campus. The facility features a variety of manufacturing tools and equipment, as well as business consultants from the SBDC, that students and community members can use for nearly any project or business venture they can dream up.

For Gettier — who holds a 25-Ton Master Captain license — those tools have allowed him to design, build and tweak prototypes for his own invention, a low-cost modular aquatic drone that will make oceanic scientific analysis more accessible and less cost prohibitive. The product he eventually aims to bring to market will allow operators to customize and deploy small, automated watercraft capable of underwater mapping, environmental observation and more.

The main goal is to reduce the barrier to entry. That was originally because I wanted to do this kind of survey work, and I didn’t have access to a lot of research funding.

Ben Gettier '26

“The main goal is to reduce the barrier to entry,” he said. “That was originally because I wanted to do this kind of survey work, and I didn’t have access to a lot of research funding.”

Operating under the business moniker Bathymetrix, a play on the scientific term ‘bathymetry’ meaning the measurement of depths of water in oceans, seas or lakes, Gettier has already produced five prototypes using SEED’s well-equipped maker spaces. He has designed parts using 3D modeling software, crafted hulls on a 3D printer and hatches on a laser cutter, all of which he has been able to fine-tune with each iterative prototype. He has also worked with members of the Longwood SBDC staff, who were the driving force behind SEED and whose offices are strategically located in the facility, to work on a business plan.

Last fall, that collaboration also earned him a spot in the prestigious VentureWell Ocean Enterprise Accelerator alongside marine-minded innovators from around the world. Administered by NOAA, the program “is designed to empower the innovators who are tackling the most critical challenges facing our oceans and coastal communities.”

Gettier took part in the Ocean Enterprise Accelerator’s Stage 0, which provides workshops, mentorship and customer discovery for budding ‘blue economy’ entrepreneurs. His biggest takeaway was confirmation and validation that his low-cost, screwless design was a viable solution to a common but unaddressed problem in the industry.

“A lot of the feedback I got was that a lot of people are having to jerry-rig their equipment in the field when something breaks,” Gettier said. “That’s why I shifted toward removing as many fasteners from my prototypes as I could, because that means fewer things that can break and fewer tools needed to fix it.”

As an alternative to screws—which can loosen and rust over time—Gettier’s newest prototypes make use of magnets to affix various sensors and equipment. Those magnets and a series of waterproof connectors allow for modular modification, which will let users customize their rig with necessary equipment, including different environmental sensors, propulsion types and more.

“You can magnetically attach whatever sensors you want, and then you can just plug everything right into the board without having to open the waterproof hatch,” he said. “Then you’re getting all that data streamed back to your laptop.”

But as is the case with nearly all novel inventions, Gettier’s road from idea to production has included setbacks that have tested his ingenuity and resourcefulness. Early versions of the prototype struggled with production setbacks. Some shorted out. Others were 3D-printed using a filament that proved to be denser than desired.

However, in a show of his entrepreneur-inventor spirit, Gettier addressed each of those setbacks as challenges and made adjustments for his next prototype. Making use of SEED’s diverse array of manufacturing equipment, he switched to a lighter, more durable filament, shored up troublesome spots in production, and designed new, magnetic hatches that allow him to troubleshoot electronics malfunctions without complicated disassembly.

“I already do boat maintenance and electrical and all that, so that’s how I have a lot of knowledge in building this stuff,” he said. “Soldering, electrical, all of that just transferred over. And I want to get into cartography, data mapping and underwater surveying, so I already knew how to get point data from sonar and coordinate data from GPS and import them into GIS to build a map. So [this project] is just kind of everything working together.”

With Gettier already in possession of those aforementioned applicable skills, knowledge and passion for the project, SEED’s maker space provided him both a dedicated facility to fine-tune his design and the tools and resources to do it. It has also put him in proximity to other like-minded Longwood students and Farmville community members working on their own projects. Some of those, including computer science, biology and business majors, have even joined Gettier on a student-led side project to construct a self-driving boat that the group will enter in the upcoming PEP Workforce Development international autonomous boat race in Portsmouth, Virginia, in April.

But for all the potential market share that his craft could one day command, Gettier remains focused on the Civitae-minded pursuits of knowledge and bettering the communities he is a part of. Despite the unique nature of his take on the aquatic drone — from low-cost production methods to a novel take on modular design — he has opted not to seek a patent. Instead, he hopes that others will join him on the course he’s setting and take his work even further.

“As a researcher, I’d rather have someone take it and make it better,” he said. “I have no problem with that.”